1)

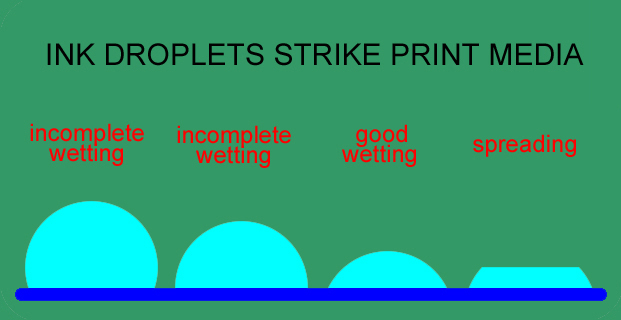

MOS-173 Wetting Agent

Surface

tension is one of the most important physical properties

of inks. Not only it determines the drop formation from

the print-head nozzle, but also determines how deep ink

drop can penetrate into media surface.

MOS-173 silicone surfactant can easily lower the surface

tension of a liquid and thus allows it to spread more

easily.

MOS-173 is

recommended for all water based printing inks which

contain a small proportion of organic co-solvent.

2)

MOS-500 Defoamer

Printers

will not perform well with foamy ink or ink that has

bubbles in it. A simple bubble can cause a complete

blockage in the line like an air embolism can cause a

stroke in a living person. So you need a defoamer to

remove air bubbles in your ink formulation system.

MOS-500 is a defoamer for use with water based

printing ink. With use of MOS-500, surface tension of

ink won't be changed dramatically. It's a very stable

and reliable defoamer.

3) MOS-176

Dispersion Resin

Dye ink is

formed from water-soluble molecules, while pigment ink

is comprised of insoluble pigment particles. Dispersion

Resin is usually used in pigment ink as a carrier to

help pigment particles suspended in ink solution.

MOS-176

is a polymer dispersion for use with water based pigment

ink.

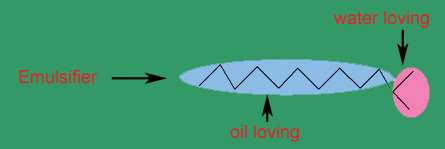

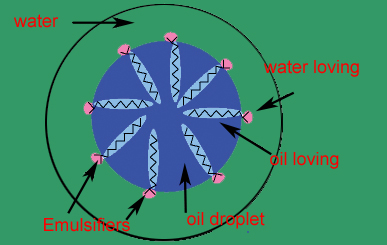

4) MOS-078

Emulsifier

At the final

stage of ink formulation, there are many ink additives,

carriers, colorants used. Some of them are water

based; while the other may be oil based. You need

a very reliable emulsifier to combine these compounds

and make your finish inks consistent and stable.

MOS-078 Emulsifier is certainly your best choice.